Drug Safety Monitoring: How the FDA Tracks Generic Drugs After Approval

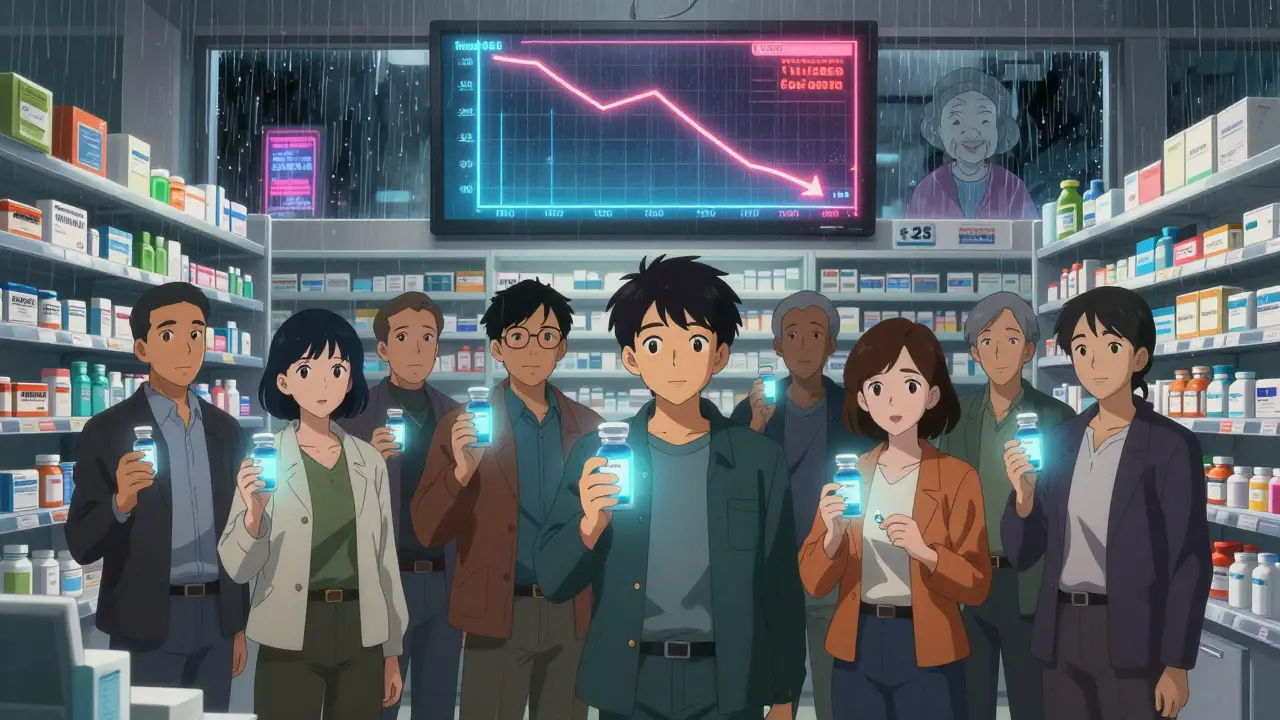

When you pick up a generic pill at the pharmacy, you expect it to work just like the brand-name version. You also expect it to be safe. But what happens after that bottle leaves the factory? How does the FDA make sure a generic drug stays safe when millions of people are taking it every day? The truth is, approval isn’t the end of the story-it’s just the beginning.

Approval Isn’t Enough

Before a generic drug hits the shelf, it must prove it’s bioequivalent to the brand-name drug. That means it delivers the same amount of active ingredient into the bloodstream at the same rate. These tests usually involve 24 to 36 healthy volunteers. It’s rigorous-but it’s also limited. You can’t catch every possible side effect in a small group of healthy people over a few weeks. Some reactions only show up after months or years of use, in older patients, or in people with other health conditions. That’s why the FDA doesn’t stop watching once the drug is approved.The FDA’s Safety Net: FAERS and MedWatch

The main tool the FDA uses to catch problems after approval is the FDA Adverse Event Reporting System (FAERS). It’s a massive database that collects reports of bad reactions from doctors, pharmacists, patients, and drug companies. In 2022, FAERS received over 2 million reports. Not all are about generics-but a big chunk are. When a pattern emerges-say, five different reports of sudden liver damage linked to a specific generic blood pressure pill-the FDA’s safety teams dig in. Anyone can report a problem through MedWatch, the FDA’s online portal. You don’t need to be a doctor. If you took a generic version of a medication and felt worse than expected-rash, dizziness, nausea, or something unusual-you can file a report. These reports are not just paperwork. They’re signals. The FDA actively mines this data, looking for trends that might be missed in clinical trials.Who’s Watching? The Teams Behind the Scenes

It’s not just one person checking emails. The FDA has dedicated teams inside the Center for Drug Evaluation and Research (CDER). The Office of Generic Drugs (OGD) leads the charge, but they work with scientists from the Office of Pharmaceutical Quality (OPQ), epidemiologists, pharmacologists, and data analysts. They meet regularly in the OGD Clinical Safety and Surveillance Committee to review new safety signals. If a generic drug made by a manufacturer in India shows a spike in kidney-related complaints, they’ll compare it to the brand-name version. If the pattern holds, they’ll investigate the manufacturing process, the inactive ingredients, or even the packaging.Manufacturing Isn’t Static-And Neither Is Safety

A generic drug isn’t just a copy of the brand-name pill. The active ingredient is the same, but the fillers, dyes, and coatings can be different. These are called inactive ingredients. For most people, that doesn’t matter. But for someone with a rare allergy to a dye, or a person with a sensitive stomach, a different coating might cause problems. The FDA doesn’t assume these differences are harmless. The Office of Pharmaceutical Quality inspects manufacturing sites-about 1,200 in the U.S. and 600 overseas every year. These inspections are often unannounced. They check everything: how raw materials are stored, how batches are tested, whether equipment is clean. A single batch of pills with too much of an impurity can trigger a recall.

The Sentinel Initiative: Real-Time Monitoring

One of the biggest upgrades to FDA’s system is the Sentinel Initiative. Launched in 2008 and expanded under the 21st Century Cures Act, Sentinel uses electronic health records from over 100 million patients across hospitals, clinics, and insurance systems. Instead of waiting for someone to report a problem, Sentinel can scan for patterns in real time. If a new generic statin is linked to a spike in muscle pain in patients over 70 in Texas, the system can flag it within weeks-not months or years. This is especially powerful for generics, because they’re used so widely. With 90% of prescriptions filled as generics, even rare side effects become noticeable quickly.What Happens When Something Goes Wrong?

The FDA doesn’t wait for a disaster. If a safety signal is confirmed, they act. Actions can include:- Updating the drug’s label to warn about a new risk

- Issuing a “Dear Healthcare Provider” letter to alert doctors

- Requiring the manufacturer to run additional studies

- Blocking new shipments or pulling the product off shelves

Why This Matters: Numbers Don’t Lie

Generic drugs make up 90% of all prescriptions in the U.S. But they cost only 23% of what brand-name drugs do. That’s why safety monitoring isn’t just a regulatory task-it’s a public health necessity. A single unsafe generic, taken by millions, can cause widespread harm. The FDA’s system is designed to catch those risks before they become epidemics. The system isn’t perfect. Experts estimate that only 1% to 10% of adverse events are ever reported. Complex generics-like inhalers or topical creams-are harder to monitor because bioequivalence is harder to prove. But the tools are getting better. The FDA’s 2022 Drug Safety Surveillance Plan includes bi-weekly data scans and more advanced algorithms to detect signals faster.

The Future: Bigger Data, Smarter Tools

By 2025, the Sentinel Initiative aims to cover 100 million patients. That’s nearly one-third of the U.S. population. The FDA is also investing in machine learning to predict which generics are most likely to have safety issues based on their manufacturing history, ingredient mix, and past reports. As more complex generics enter the market-like long-acting injectables or drugs with narrow therapeutic windows-the need for smarter monitoring grows. The Generic Drug User Fee Amendments (GDUFA III), which started in 2023, give the FDA more funding to hire analysts, upgrade software, and expand inspections. The goal? To keep generics affordable without compromising safety.What You Can Do

You don’t have to wait for the FDA to find a problem. If you notice something off after switching to a generic-new side effects, less effectiveness, unusual reactions-talk to your doctor. And report it. Go to MedWatch and file a report. Your input helps. The system works best when it’s filled with real-world data from real people.Are generic drugs less safe than brand-name drugs?

No. Generic drugs must meet the same strict standards for quality, strength, purity, and performance as brand-name drugs. The FDA requires them to be bioequivalent and manufactured under the same good practices. The main difference is cost-not safety. Post-approval monitoring ensures that any unexpected issues are caught quickly, whether the drug is generic or brand-name.

Can inactive ingredients in generics cause problems?

Yes, in rare cases. While the active ingredient is identical, generics can use different fillers, dyes, or coatings. For most people, this doesn’t matter. But if you have allergies (like to lactose, gluten, or certain dyes) or digestive sensitivities, you might react to these differences. If you notice new symptoms after switching to a generic, check the label for inactive ingredients or ask your pharmacist. Reporting the issue helps the FDA track patterns.

How often does the FDA recall generic drugs?

Recalls are uncommon but do happen. Most are voluntary and prompted by manufacturing issues-like contamination, incorrect dosage, or impurities exceeding safety limits. In 2022, the FDA issued over 100 drug recalls, about half of which involved generics. These aren’t usually about safety in the way side effects are-they’re about quality control. The FDA’s inspection program catches most of these before they reach patients.

Why does the FDA monitor generics differently than brand-name drugs?

The FDA doesn’t monitor them differently in goal-but the methods are adapted. Brand-name drugs go through large clinical trials with thousands of patients before approval. Generics rely on bioequivalence studies with fewer participants. So, the FDA leans more heavily on post-market data-like FAERS, Sentinel, and manufacturing inspections-to fill the gap. The system is designed to catch what pre-approval studies can’t: rare reactions, long-term effects, and quality issues that emerge over time.

Can I trust a generic drug from another country?

Yes-if it’s approved by the FDA. All generic drugs sold in the U.S., no matter where they’re made, must meet the same FDA standards. The agency inspects over 600 foreign manufacturing sites each year. Many top generic manufacturers are based in India and China, but they’re held to the same quality controls as U.S. plants. The FDA doesn’t treat foreign-made drugs as second-class. They’re inspected just as often, and their data is reviewed just as carefully.

Comments

Sheryl Dhlamini

January 29, 2026 AT 21:23So I switched to a generic blood pressure med last year and started getting these weird dizzy spells. Thought it was just stress-until I read this. Filed a MedWatch report last week. Felt like I was shouting into the void, but now I feel like maybe I actually helped? 🙌

Doug Gray

January 30, 2026 AT 11:20FAERS is essentially a garbage fire of anecdotal noise masquerading as pharmacovigilance. The signal-to-noise ratio is so low it’s practically entropic. You need Bayesian hierarchical modeling, not crowd-sourced whining. Also, why are we still using 1970s-era reporting systems in the age of AI? 🤔

LOUIS YOUANES

February 1, 2026 AT 02:28Let’s be real-the FDA is just a PR front for Big Pharma. They approve generics from India because it’s cheaper, then pretend they’re watching. Meanwhile, your grandma’s heart pill has more fillers than a Walmart donut. And don’t get me started on the ‘unannounced inspections’-those are scheduled 3 months in advance and the plant cleans up like it’s for the Queen. 🤡

Laia Freeman

February 1, 2026 AT 13:13OMG YES!! I switched to a generic Adderall last month and felt like I was drugged with glitter. Like, my brain was just… floating?? I thought I was losing it. Then I checked the inactive ingredients-lactose monohydrate. I’m lactose intolerant!! I went back to brand and BOOM-back to normal. Why isn’t this on the label??!!??

paul walker

February 2, 2026 AT 08:15My mom’s on a generic statin and had muscle pain for months. Doctor said it was ‘just aging.’ We reported it. Three months later, the label got updated. Turns out, it’s not just me. People are scared to speak up. Don’t be. Your voice matters.

Alex Flores Gomez

February 2, 2026 AT 11:43Anyone else notice how the FDA only ‘reacts’ after a drug’s been on the market for 3+ years? That’s not surveillance-that’s triage. Real oversight means pre-market post-marketing risk modeling. But nah, let’s just wait for 500 people to get liver failure before we do anything. Classic.

Frank Declemij

February 2, 2026 AT 13:37The Sentinel Initiative is the most promising development in post-market surveillance in decades. Leveraging real-world electronic health records at scale allows for near-real-time detection of adverse events that clinical trials simply cannot capture. This is evidence-based pharmacovigilance at its best.

Pawan Kumar

February 3, 2026 AT 12:01India and China manufacture 80% of the world’s generics. The FDA inspects 600 sites annually? That’s one inspection every 1.5 days per country. Impossible. The entire system is a façade. The real reason generics are cheap is because they cut corners-silica dust in pills, unsterile labs, falsified batch records. The FDA knows. They just don’t care.

ryan Sifontes

February 3, 2026 AT 19:00They say ‘report it’ like it matters. I reported my rash after taking a generic ibuprofen. Got an auto-reply. Two years later, same problem with another batch. Nothing changed. The system is broken. We’re just lab rats with better insurance.

Laura Arnal

February 5, 2026 AT 12:35Y’all, if you’ve had weird side effects with a generic-REPORT IT. Seriously. I used to think it was ‘just me’ until I found out 12 other people had the same reaction to the same batch. The FDA needs our data. It’s not just paperwork-it’s protection. ❤️

Eli In

February 7, 2026 AT 04:03My abuela takes generic metformin from Mexico (FDA-approved, I checked). She’s 78, diabetic, no side effects. But she also has a daily walk, eats beans, and prays before every pill. Maybe safety isn’t just about labs and algorithms. Maybe it’s also about community, care, and consistency. 🌿

Megan Brooks

February 9, 2026 AT 03:52The structural asymmetry between brand-name and generic drug development is ethically defensible only if post-market surveillance is robust, transparent, and adequately resourced. The current system, while technologically sophisticated, remains underfunded and reliant on voluntary reporting-a clear vulnerability. We must treat pharmacovigilance as a public good, not a bureaucratic afterthought.